Used Engines for Sale: What You Need to Know Prior To Acquiring One

Used Engines for Sale: What You Need to Know Prior To Acquiring One

Blog Article

Essential Factors To Consider for Ensuring High Quality and Longevity being used Engines

When taking into consideration the acquisition of a used engine, guaranteeing its top quality and long life needs a diverse method. Maintenance history is an essential factor, as it offers insight into the engine's past care and possible future integrity. Past paperwork, a comprehensive evaluation of physical parts-- such as belts, hoses, and seals-- can disclose hidden problems. Efficiency testing is also crucial, using a snapshot of the engine's functional performance. However, comprehending the nuances of these analyses and their implications can be intricate. What are the essential techniques that can be used to navigate this intricate analysis procedure effectively?

Engine History Analysis

In the realm of used engines, a complete engine history evaluation is critical to making certain high quality and dependability. Understanding an engine's past can offer essential insights into its efficiency capabilities and potential future long life.

Engines that have undertaken considerable repair work might have underlying problems that could resurface. Checking out the engine's mileage can serve as an indication of wear and tear. An engine used primarily for long-distance freeway driving may be in better condition than one subjected to constant stop-and-go city web traffic.

In significance, an exhaustive examination right into an engine's background is necessary for making enlightened buying decisions. used engines for sale.

Comprehensive Evaluation Overview

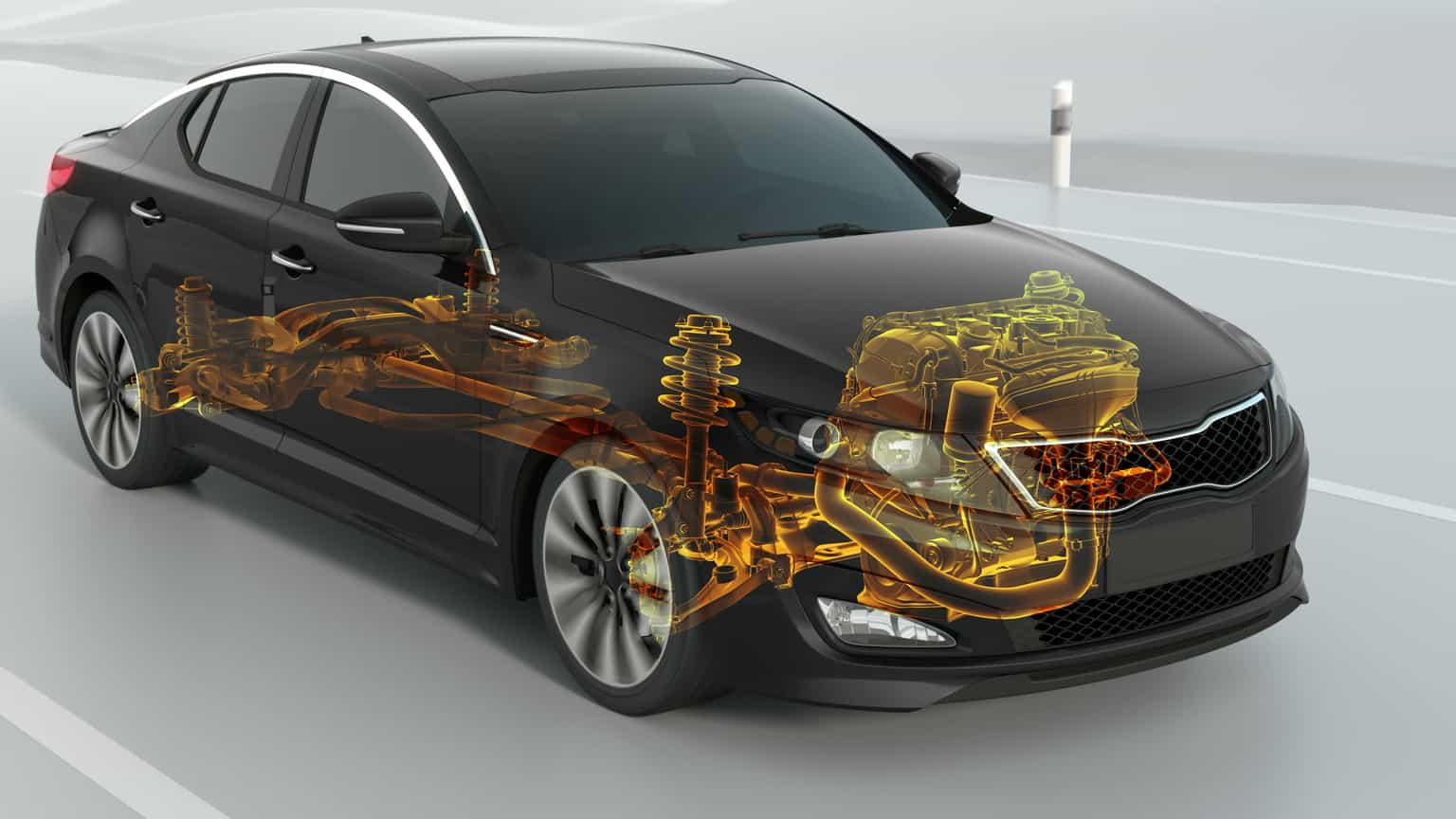

While recognizing an engine's history gives important context, a thorough evaluation is the following step to ensure its existing condition straightens with historical data. The examination must begin with a visual analysis, checking for indicators of leaks, deterioration, and unusual wear. Evaluate the exterior for oil spots or coolant marks, which may suggest underlying concerns.

Next, assess the engine's placing system for any loose screws or irregularities that could impact efficiency. Pay attention to the problem of belts and tubes, as these components are essential for optimal engine performance. Analyze for fractures, fraying, or any kind of signs of damage.

Recognizing Damage

Acknowledging signs of deterioration is critical for analyzing a used engine's long life and dependability. It involves a meticulous exam of different engine components to establish their present state and prospective future efficiency. Typical indicators consist of visible deterioration, which can impact metal components and jeopardize structural honesty. Corrosion on or around the engine block, cylinder heads, and exhaust manifolds is specifically worrying.

An additional important aspect is evaluating the engine's seals and gaskets. These elements are important for keeping appropriate stress and preventing fluid leaks. Proof of oil leakages or used gaskets usually suggests wear and tear, potentially causing more serious concerns if not addressed quickly. In addition, abnormal noises during engine procedure, such as knocking or ticking audios, may indicate interior damages or too much endure moving parts like pistons or bearings.

The condition of belts and pipes is equally crucial, as they play a crucial role in the engine's overall feature. Cracked or torn belts and weak tubes are indicators old that could result in engine failing if neglected. Finally, checking out the oil problem and filter can provide understandings right into previous upkeep methods, as filthy oil or stopped up filters recommend disregard and sped up wear.

Performance Testing Basics

Evaluating the wear and tear of engine components establishes the phase for a thorough analysis via efficiency testing. Performance screening functions as an important procedure in identifying the operational honesty of an utilized engine. By mimicing real-world problems, it examines the engine's capability to deliver power successfully and dependably. Secret metrics Get More Info consist of horsepower, torque, gas effectiveness, and emissions degrees. This data gives useful insights right into the engine's current efficiency and assists recognize prospective issues that might not be instantly noticeable.

Using dynamometers is a typical approach in efficiency screening. These gadgets measure the engine's result throughout different problems, using an in-depth profile of its capability. Additionally, on-road testing enhances dynamometer assessments by observing engine habits under regular driving scenarios, ensuring it fulfills the called for standards for both security and performance.

Advanced diagnostic tools additionally boost the capability to identify underlying problems. These devices assess engine management systems, recognizing faults in electronic elements that might influence performance. Comprehensive testing not only confirms the engine's functional standing but likewise help in forecasting future maintenance needs. This makes certain the made use of engine can deliver trusted performance over an extended period, thus maximizing its value and life span.

Maintenance and Care Tips

Correct upkeep and treatment are vital to lengthening the life expectancy of an utilized engine and ensuring its consistent performance. Normal oil adjustments are paramount; making use of the producer's recommended oil kind and quality can protect against excessive deterioration. Additionally, oil filters need to be replaced simultaneously to preserve optimal lubrication and cleanliness within the engine.

Keeping an eye on fluid levels, including coolant, transmission fluid, and brake liquid, is essential. Ensuring these liquids are at appropriate degrees assists prevent getting too hot and various other mechanical issues. Evaluating belts and tubes for indications of wear, such as cracks or fraying, can avoid prospective failures that might result in costly fixings.

Routine inspection of the air filter is additionally required, as a tidy filter guarantees efficient air flow and combustion, therefore enhancing engine performance. Trigger plugs must be checked and changed when needed to maintain effective fuel burning and prevent engine misfires.

Finally, regular analysis checks making use of expert devices can determine their website potential concerns prior to they come to be significant issues. By sticking to these maintenance and treatment tips, utilized engine owners can guarantee their engines continue to be reputable, reliable, and with the ability of performing well over a prolonged duration.

Verdict

Report this page